Zeiss Scanners

#HandsOnMetrology

PARTNER

Structured Light Systems

- Capture a 3D Data Cloud of your part in a matter of minutes

- Uses 3D Blue Light Structured Technology

- Ambient Light does not influence results

- Create a STL file in matter of minutes

- Inspect your part against a CAD Model using ZEISS Inspect Software

- A vast range of applications:

– Quality control / inspection

– Tool and model making

– Design

– Rapid manufacturing

– Reverse engineering

– Archeology, documentation of art-historical objects, etc.

Scan 1

- Great Performance at a great price

- Three sizes, 100, 200, & 400mm

- Accuracy of .0007” over 40” cube

- 6 MB Camera

The sensor recognizes changing ambient conditions during operation and can compensate for these changes.

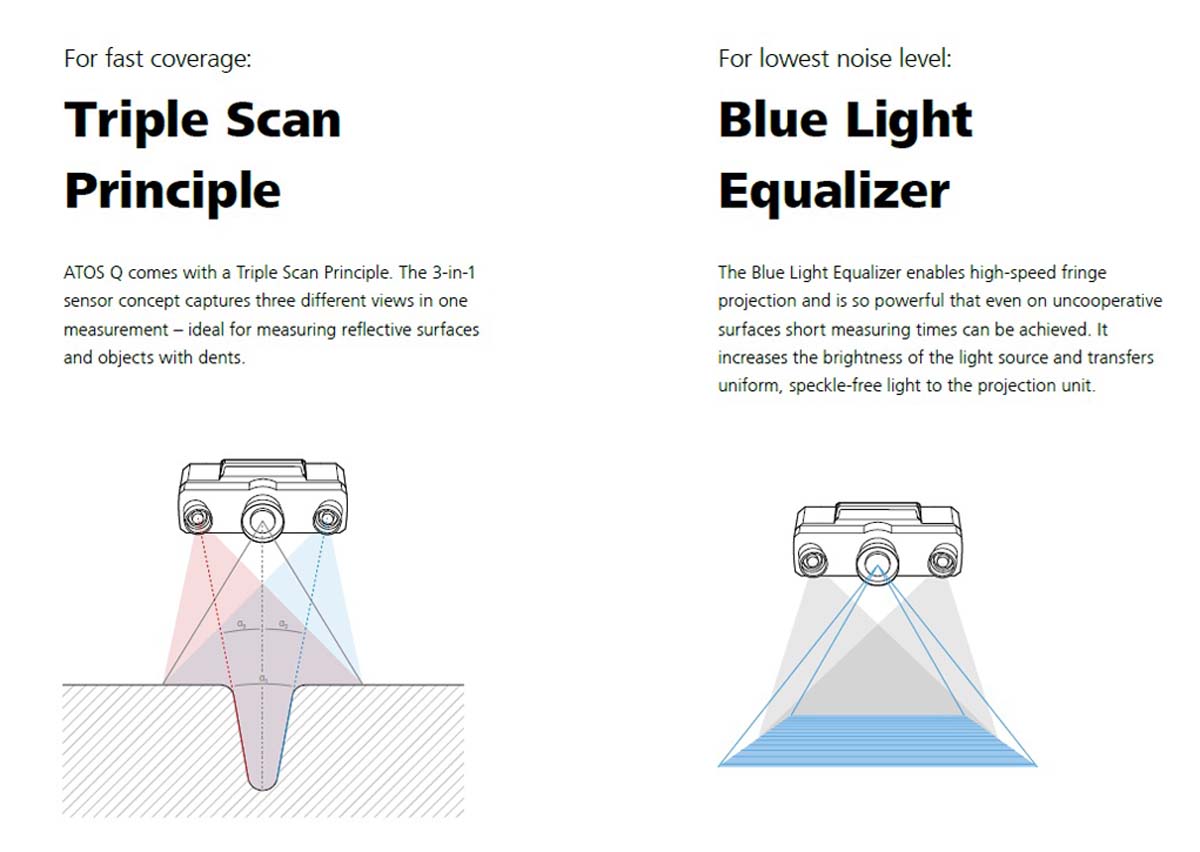

ATOS Q

- For very demanding applications and inspection tasks

- 8MB or 12MB Camera

- Interchangable Lenses for different measuring volumes 100, 170, 270, 350, 500mm

- Precise fringe patterns are projected onto the surface of the object and are captured by two cameras based on the stereo camera principle.

- Dustproof and splashproof – making it ideally suited for taking a project from the measuring room to production.

- The Blue Light Equalizer enables high-speed fringe projection and is so powerful that short measuring times

can be achieved even on optically uncooperative surfaces.

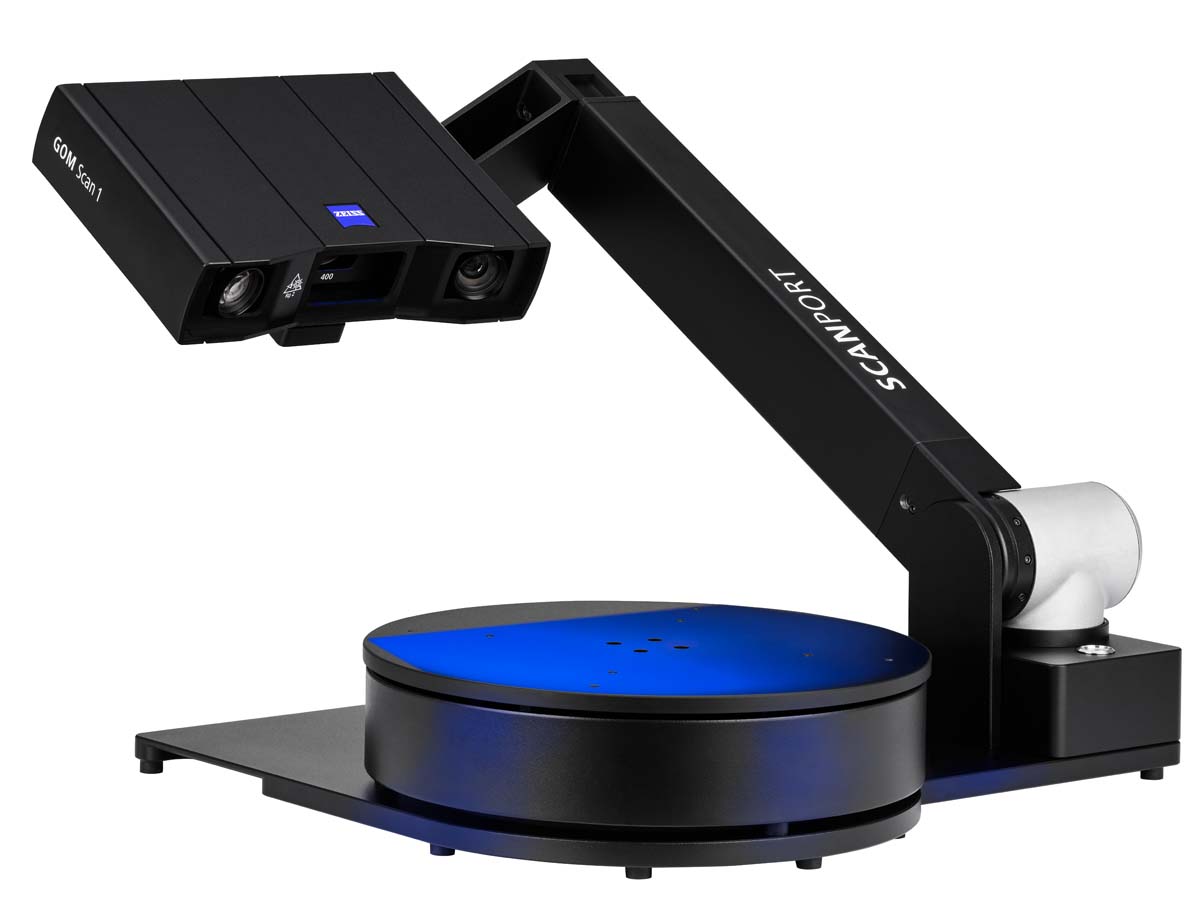

ScanPort

- A complete solution for 3-axis automation

- Mobile, can get a travel case

- Push a button and walk away

- Works with Scan1 or ATOS Q system

- Priced very well

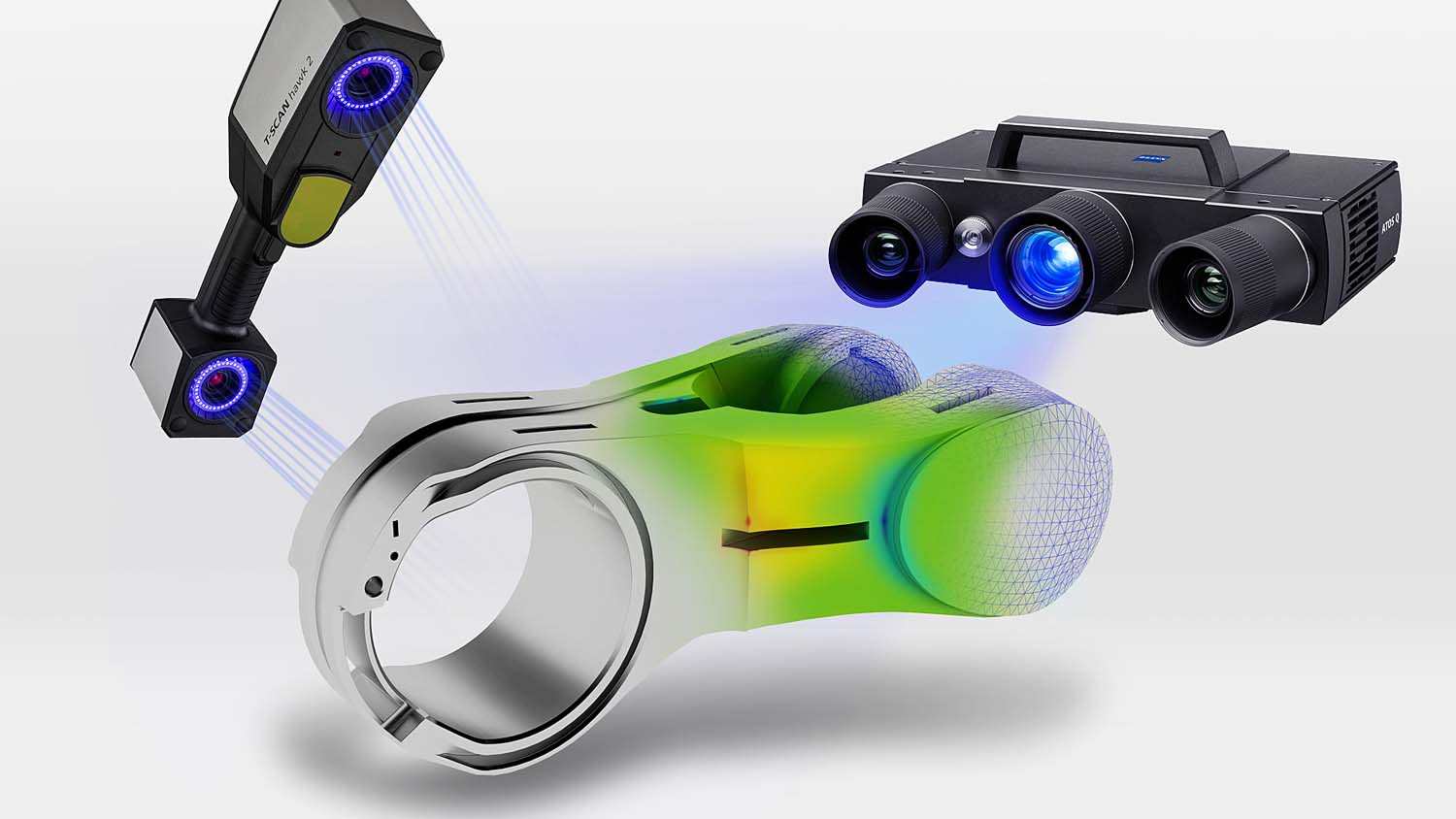

T-Scan Hawk 2

- Most accurate scanner in the industry

- Small parts to large parts

- Lightweight

- Intuitive controls without needing a keyboard

- A red laser marker helps you to easily adjust for perfect scanning results.

- Selectable Higher resolution button for detailed scanning.

- Scan objects up to multiple meters in size with satellite mode.

Four Buttons gives you full control of the system without having to use a keyboard

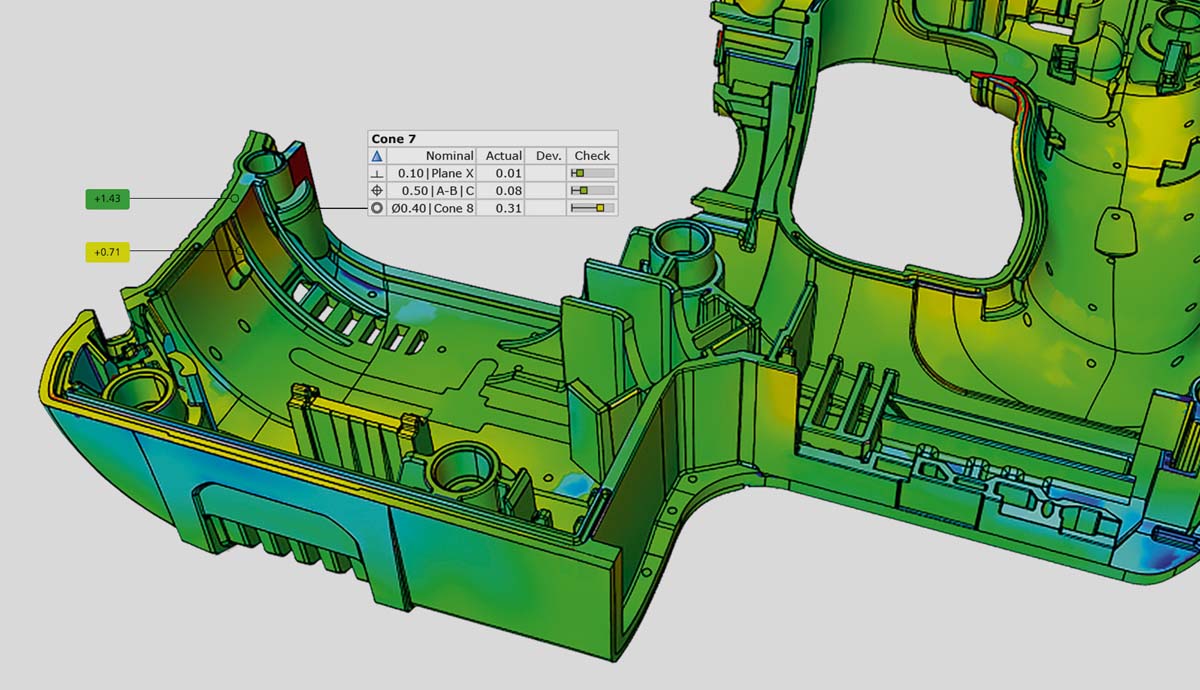

ZEISS Inspect

- Data captured with fringe light scanners, laser scanners, industrial CT-scanners, as well as coordinate measuring machines.

- Comprehensive integration of measurements and analyses, clearly arranged in one system.

- It allows to import native formats, like CATIA, NX, Solidworks and Pro/E, and even PMI. No need to convert data.

- It records each inspection step, allowing measurement plans to be easily tracked, repeated, and adjusted.

- Generate customized scripts

- Trend Analysis

- Compare several parts within one project

- Fast and simple defect inspections

- Accurate nominal-actual comparison

- Various reporting options

- Best scanner software on the market.

ZEISS Reverse Engineering Software

- Create CAD models quickly and simply from polygon meshes or point clouds

- Surface reconstruction and tool correction

- Powerful surface reconstruction software

- Import your STL or PLY data and ASCII formats

- Edit your measuring data with practical functions for STL data, such as filling holes or smoothing surfaces

- Software has “Surface approximation to points” when converting your data

- Special engineering tools for accurately remodeling flowing, organic shapes

- Even faster to CAD thanks to 2D-Sketching